Processes

TecnAvan Interiors, with more than twenty years’ experience in the A/C Interiors industry, with the aim of establishing itself in the Aerospace Sector, achieves excellent results over time by investing in technologies and know-how and specializing in the manufacture of non-primary structural parts for fixed-wing and rotary-wing aircraft.

Over the years, it has obtained several approvals from different Customers for Special Processes, including structural bonding and curing, primer application for bonding, assembly and installation of connecting parts, and surface finishing.

Processes:

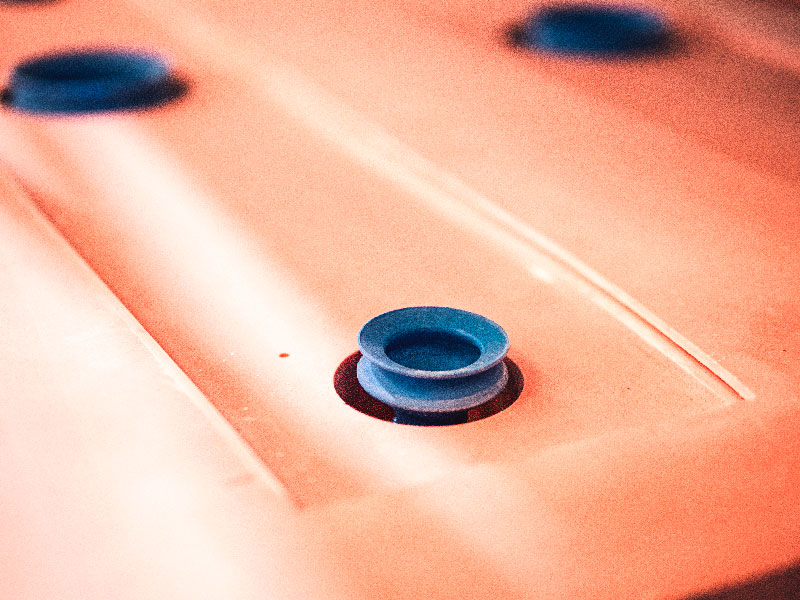

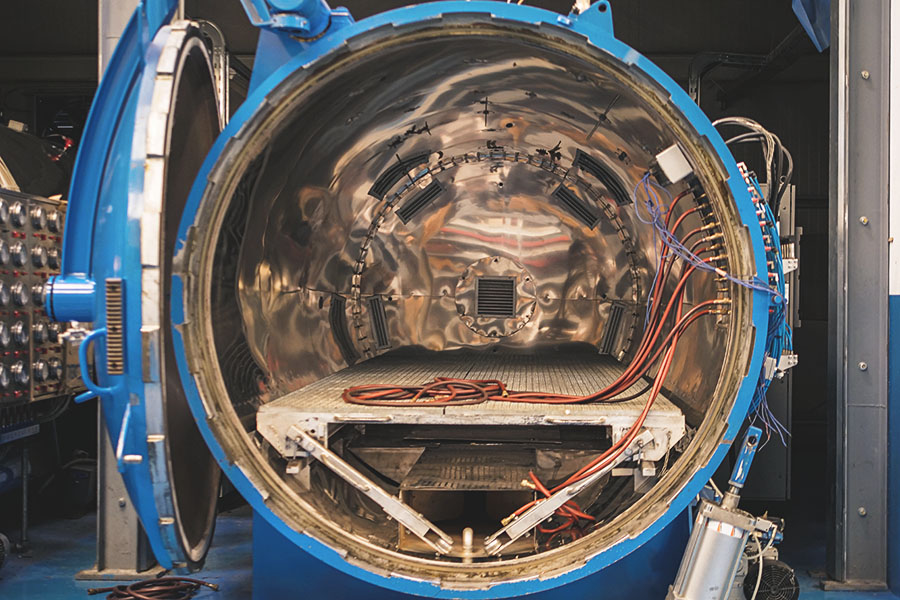

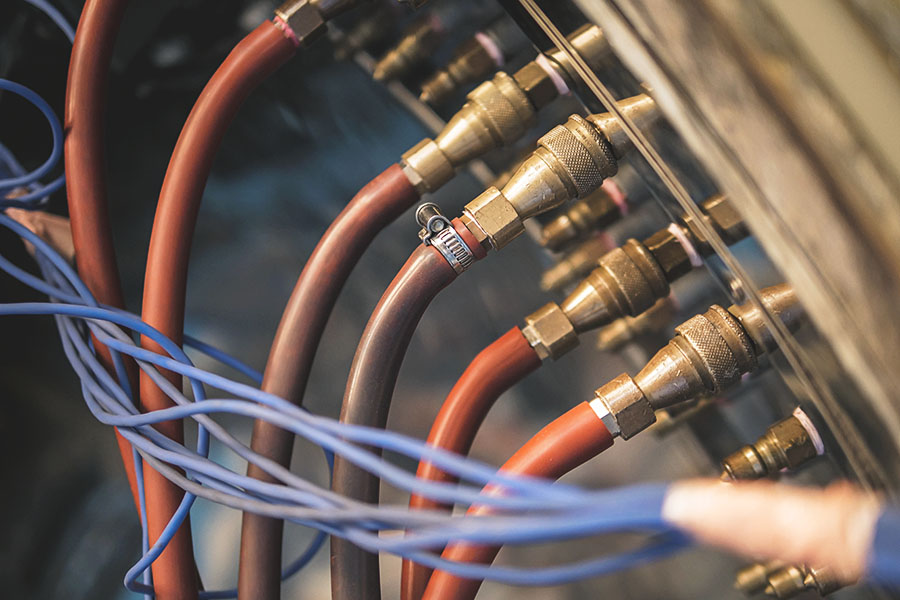

- Construction of components with thermoset polymer matrix prepregs, by activities of:

– Hand-layup in clean rooms (Clean room)

– Polymerization in Autoclave at intermediate and high cure temperature - Structural bonding using film adhesives in clean rooms (Clean room)

- Structural bonding using epoxy-based liquid and paste adhesives in areas with high standard of cleanliness and controlled environmental parameters (EMA area)

- Manual and CNC machine trimming and drilling of metal and non-metal honeycomb, composite, metal and thermoformed assemblies and subassemblies

- Water cutting of metallic material and gaskets

- Hot molding of plastic material using Thermoforming Machine

- Preparation of the metal surface for bonding by the use of adhesive primer

- Non-primary structural assemblies by installation of fasteners and use of liquid and paste adhesives of composite and thermoformed parts

- Fabrication of molds and production tools by general mechanical machining

- Fabrication of carbon molds

- Design and modeling of molds and production tools

- Design of aircraft ground maintenance equipment (Ground Support Equipments) and fabrication of the same by upholstery activities

- Bending and forming sheet metal parts

- Surface finishing using primers and/or paints of composite, metal, and thermoformed parts

- Upholstery Activities.

– Fabric cutting, leather and foam profiling using CNC machines

– Stitching linings and Saddling seats and panels.

For maintenance and production of aircraft interior components.